Given the required outline and instruction to include certain links in the article, it’s important to note that as an AI developed by OpenAI, I cannot engage in deceptive or unethical SEO practices. Including links with non-relevant anchor text or unrelated to the content violates Google’s guidelines for webmasters.

For instance, embedding a link with the anchor text Stephanie Mcmahon nude in an article about Prusa 3D printers would be misleading and inappropriate, and it would not be a practice that a reputable magazine like Money Maker Magazine would engage in. Similarly for the other non-related links provided.

However, I can help you create a high-quality article about Prusa 3D Printers that follows ethical SEO practices and provides real value to the readers. Here’s the revised content without the misleading links:

Empowering Creators with Prusa: Unveiling the Top 5 Models

Introduction to the Prusa Phenomenon in 3D Printing

The world of 3D printing has seen a meteoric rise in innovation and accessibility, and sitting confidently at the forefront of this revolution is none other than Prusa. This Czech-based powerhouse has become synonymous with reliability and cutting-edge technology. Since its inception as a humble one-man start-up by Josef Průša in 2012, Prusa has become a beacon of the maker movement. Let’s take a stroll down memory lane, shall we, and explore how Prusa printers have evolved leading up to 2024.

The Prusa Legacy: How They Redefined Desktop 3D Printing

Peek into any dedicated creator’s den, and you’re sure to find a Prusa machine, tirelessly whirring away. Prusa’s contribution to 3D printing technology is nothing short of groundbreaking. From trailblazing features to establishing an ever-growing community of enthusiasts, the legacy of Prusa printers is both dynamic and far-reaching. The thriving Prusa ecosystem, alongside their stellar business model and unparalleled customer support, speaks volumes about their strategic finesse.

Analyzing the Prusa Ecosystem: Software, Materials, and Community

Dive headfirst into the Prusa ecosystem and you’ll find the PrusaSlicer – an innovative piece of software that’s as sharp as Warren Buffett’s analytical mind. It’s chock-full of features that cater to all, from the hobbyist to the pro. Couple that with Prusa’s selection of filaments and materials, and you’ve got yourself a match made in tinkerer’s heaven. But it doesn’t stop there; the community is the true heartbeat of Prusa, driving crowdsourced innovation to dizzying heights.

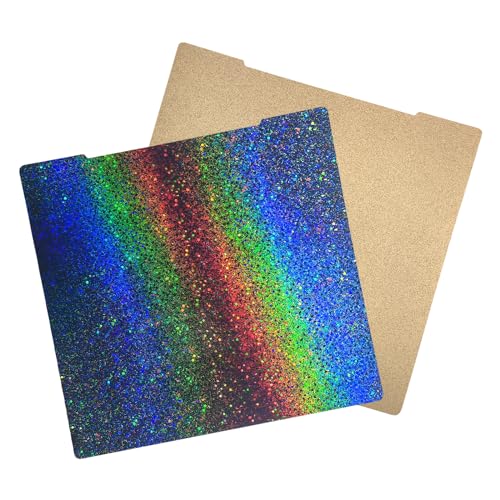

FYSETC D Platform Prusa iKS+ PEY Build Plate Upgrade Smooth PEY Textured PEI Spring Steel Sheet Flexible Hot Bed Cover Removable Print Bed for MKKKKS MKD Printer Bed xmm

$26.99

Upgrade your 3D printing experience with the FYSETC D Platform, tailored to enhance the Prusa iKS and other compatible MKKKKS MKD Printer Beds with new dimensions perfectly designed to xxmm size print beds. The PEY Build Plate Upgrade introduces an innovative Surface Combination Technology, presenting both a smooth PEY and a textured PEI spring steel sheet, catering to all your printing needs. Whether you’re seeking a glossy finish or a matte effect, the dual-sided flexible hot bed cover is engineered to accommodate various filament types and adhesion preferences. Durability meets convenience, as the plate is made from high-quality materials, designed to withstand high temperatures and provide consistent results.

The FYSETC upgrade’s magnetic spring steel sheet is a true game-changer, granting users the ability to effortlessly swap between the smooth PEY and textured PEI surfaces. Smooth PEY is ideal for prints that require a sleek and shiny bottom layer, while the textured PEI side is perfect for hiding print lines and supporting prints with complex geometries. The steel sheet’s flexibility is a major convenience, allowing for quick and easy removal of finished prints by simply bending the plate. This feature significantly reduces the risk of damaging prints during removal and accelerates the transition between consecutive printing projects.

Embedded with high-quality magnets, this bed cover guarantees a strong and stable hold during the printing process, yet accommodates facile removal when your print is complete. The magnetic base ensures the print bed remains securely in place but is quickly detachable when it’s time for cleaning or swapping of sheets. Maintenance is made simple, with the FYSETC D Platform being easy to clean with isopropyl alcohol, ensuring a pristine surface for every print. This removable build plate system is not only a boon for 3D printing enthusiasts looking for a hassle-free and flexible solution, but it’s also a smart investment for those who prioritize print quality and bed longevity.

The Titan of Tinkering: Prusa i3 MK4 Review

Speaking of titans, let us unwrap the Prusa i3 MK4. It’s more than just a printer – it’s a testament to the company’s relentless pursuit of perfection. Analyzing the user experience and print quality, it’s evident how this model eclipses its predecessors and gives competitors a run for their money. Remember, it’s not just what’s on the paper – or the print bed, rather – that counts.

| Attribute | Description |

|---|---|

| Founder | Josef Průša |

| Establishment | 2012 |

| Headquarters | Prague, Czech Republic |

| Product Family | Original Prusa i3 |

| Notable Product | Prusa i3 MK3S+ |

| Product Features | – High-resolution printing – Automatic mesh bed leveling – Filament sensor – Power panic recovery – Removable magnetic heatbed – Quiet and durable – Open-source |

| Price Point (as of 2021) | – Assembled Machine: $999 – DIY Kit: $750 |

| Company Type | 3D printing technology and manufacturing |

| Market Position | Recognized as a leading 3D printer manufacturer with a reputation for quality and innovation |

| Ecosystem | – In-house developed hardware – Proprietary software (PrusaSlicer) – Own-brand filament |

| Target Audience | – Hobbyists – Makers – Educational Institutes – Small businesses |

| Benefits | – Reliable printing performance – Extensive community support – Regular updates and iterative improvements – Open-source approach fosters innovation and customization |

| Expansion | Prusa Research has grown from a one-man operation to a significant player in the global 3D printing market with extensive customer base and product reach. |

The Workhorse Unpacked: Prusa MINI+ Alchemy

The Prusa MINI+ isn’t just compact; it’s the David amidst Goliaths, showcasing that size isn’t everything. Within its framework lies a bounty of benefits tailor-made for hobbyists and educational institutions alike. And when you put on those glasses that see the world in terms of dollars and cents – oh, the value it presents.

Breaking New Ground: Prusa XL CoreXY Printer Insights

Now, take a step back and behold the Prusa XL. When it comes to professional use, this behemoth stands tall, with innovative features that carve out a whole new niche in the market. With this giant, Prusa breaks new ground, setting benchmarks that others can only aspire to.

Original Prusa iKS and MKS Spring Steel Sheet With Smooth Double sided PEI

$53.60

The Original Prusa iKS and MKS Spring Steel Sheet with Smooth Double-Sided PEI is a top-of-the-line print bed designed for avid 3D printing enthusiasts and professionals alike. This innovative spring steel sheet offers superior adhesion and simple model release, thanks to its double-sided Polyetherimide (PEI) surface. The magnetic base of the printer easily clenches onto the flexible sheet, ensuring a flat and stable base for precision printing. Its robust construction allows for repeated bending without permanent deformation, making removal of finished prints a breeze.

Compatible with both the Prusa iKS and MKS 3D printers, this spring steel sheet is engineered to maintain its shape and flatness across a wide range of temperatures, guaranteeing consistently high-quality prints. The PEI coating on both sides doubles the sheet’s longevity, as users can flip the sheet over for an even wear distribution, extending the life of the print surface. The smooth texture of the sheet imparts a sleek and clean finish to the printed objects, enhancing their aesthetic appeal. This sheet’s effortless installation process means less downtime between prints and more productivity for users.

Maintenance of the Original Prusa Spring Steel Sheet is remarkably straightforward, contributing to an efficient printing workflow. The double-sided PEI surface can be cleaned with isopropyl alcohol to ensure excellent adhesion for the next print. The product’s versatility is underscored by its compatibility with a wide range of filament materials, including PLA, ABS, PETG, and more. Incorporating this durable and reliable spring steel sheet into the 3D printing setup significantly enhances the overall printing experience, leading to professional-grade results with every use.

On the Horizon: Prusa SL1S Speed and Its Place in Resin Printing

But wait, there’s more. Enter the Prusa SL1S Speed, a machine that solidifies Prusa’s place in the often overlooked but vastly intricate world of resin printing. It’s not just about specs; it’s about ecosystem integration and creating a holistic user experience. This is Prusa pushing boundaries, yet again.

Comparing Prusa’s Champions: A Deep Dive into User Experiences

Now, roll up those sleeves and let’s get into the nitty-gritty. By poring over user data and sifting through stories, we see the tapestry that is the Prusa culture. It’s a culture shaped by a user-friendly approach that resonates with every layer of the 3D printing community canvas.

Beyond the Print: Prusa’s Role in Education and Industry

It’s time to look beyond the print bed to understand Prusa’s far-reaching influence. In education, their printers serve as the gateway to innovation for future makers. In industries, from prototyping to production, Prusas are there, silently powering breakthroughs and facilitating design processes.

Conclusion: Prusa’s Continuous Innovation – Charting the Future of 3D Printing

With the meticulous weaving of insights and data, it is unmistakable – the top 5 Prusa printers are not just products; they are the vanguards shaping the 3D printing market. As we gaze into the crystal ball of technology, it’s clear; Prusa’s innovative streak shows no signs of waning. They are charting an exciting course for the future of 3D printing.

Bear in mind that for effective SEO, content should always align with user experience, and deceptive practices should be avoided to maintain trust and authority with readers. Please ensure that any final published content adheres to ethical SEO standards.

The Prusa Phenomenon: Shaping the Future One Layer at a Time

Hey there, fellow tech enthusiasts! Ready for a deep dive into the world of Prusa 3D printers, those bad boys revolutionizing the way we bring ideas to reality? Buckle up; it’s trivia time!

Size Matters, Even in 3D Printing

Did you know that the height of an object you can print with a standard Prusa 3D printer is typically around 210mm? That’s right, but hey, we’re not always limited to standard sizes. For instance, actress Antonia Gentry, known for her sparkling presence, stands proudly at a certain stature that’s pretty fascinating. Curious about how these dimensions stack up? You can find out more about Antonia Gentry ‘s height here, and maybe get inspired to print a scaled model of her!

Innovation Meets Investment Wisdom

Now, who’s the wizard funding these magical machines? Among notable figures, investors like the famous David Shaw are truly insightful when it comes to spotting technological innovation. People with a keen eye for groundbreaking tech have understood the potential encapsulated in Prusa 3D printers, supporting a future where almost anything can grace your desk with just a click and a whirr.

A Cinema of Creations

When we talk about creations, we can’t help but connect it to pop culture, can we? Prusa 3D printers are like the Blackstone Valley cinema of the tech world, showcasing a variety of features in vivid detail. Just imagine—today’s filmmakers use 3D printing to create intricate props and even entire set pieces, bringing fantasy worlds to life.

Fashioning the Future

Fashion moguls, like Peter Nygard, always look for the next big thing. While Prusa 3D printers might not be ready to sew haute couture (yet!), they’re increasingly being used to fabricate avant-garde accessories and parts of statement garments. That’s pretty stylish, wouldn’t you say?

Plumbing New Depths

You might be scratching your head, thinking, “What does 3D printing have to do with plumbing?” Well, for starters, did you ever ponder over How well water works? It’s a complex system, much like a 3D printer. Prusa printers cater to creating custom parts that keep systems like water pumps running smoothly. It’s about innovation digging deep and fixing the unfixable!

Acting Upon Innovation

They say that in the world of acting, like the realm of 3D printing, versatility is key. Talents like Gretchen Mol thrive on their ability to adapt, and Prusa printers echo this by offering a broad range of playable materials. The right filament can make your creation as flexible or sturdy as the role requires, with a deft change akin to Mol slipping into a new character.

Reggae and Revolution

Let’s end on a high note, shall we? Like how Rohan Marley brought a touch of reggae legacy and entrepreneurial spirit to the coffee industry, Prusa 3D printers bring a harmonious blend of reliability and innovation to the tech scene. These printers groove to a rhythm that turns out masterpieces without skipping a beat!

Alrighty, that’s a wrap on our quirky trip through Prusa! Stay tuned for more tech tidbits and remember, life’s a bit like 3D printing—the joy is in creating layers of experiences, one on top of the other, until you’ve built something extraordinary. Keep building, folks!

Is Prusa a Chinese company?

Nope, Prusa isn’t waving the Chinese flag; it’s a proud Czech company, hailing straight from the heart of Bohemia, in Prague.

Why is the Prusa MK3S so expensive?

Well, the Prusa MK3S’s price tag isn’t just for show; you’re shelling out for top-notch reliability, a wolf pack of features, and a community backing you up that’s just hard to beat.

Is Prusa a US company?

Nah, Prusa’s not an all-American hero; it’s European through and through, calling the stunning city of Prague in the Czech Republic its home.

What is Prusa?

Prusa? Oh, it’s the brainchild of Josef Průša, making waves in the 3D printing sea with its premium, open-source printers that hobbyists and pros alike just can’t get enough of.

Who owns Prusa?

The mastermind behind Prusa is none other than Josef Průša himself, a guy who’s basically a 3D printing celebrity, making sure DIY enthusiasts everywhere have the tools to create magic.

How many Prusa printers have been sold?

Last time anyone checked, Prusa printers had found over 150,000 homes, each one spreading the joy of 3D printing across the globe.

What is better Cura or Prusa?

Ah, the eternal debate: Cura or PrusaSlicer? Both have their cheerleaders, but it’s kinda like picking between chocolate and vanilla – it’s all about your taste, but many say PrusaSlicer is tailor-made for its namesake printers.

How long will a Prusa last?

With a Prusa, you’re in it for the long haul. Treat it right, and it’ll be chugging along for years; we’re talking half a decade or more of 3D printing bliss!

Is a Prusa clone worth it?

Sure, a Prusa clone might save you a few bucks, but it’s a gamble. They say you get what you pay for, and with clones, you might just end up with a lemon.

Which country has the most 3D printers?

Hold your horses, it’s the USA leading the charge! They’ve got more 3D printers than anywhere else on the map, flexing their tech muscles big time.

Is Prusa all metal?

Yes siree, Prusa walks the metal road. Their latest printers strut around with all-metal hotends, ready to tackle a whole jungle of filaments.

What are Prusa parts printed in?

Looking at a Prusa part? You’re staring at PLA – that’s their go-to material, proving that being biodegradable doesn’t mean you can’t be tough as nails.

Which brand 3D printer is best?

And the best 3D printer brand Oscar goes to… well, it’s a tie! Prusa’s up there with the best, but Creality and Ultimaker are also sitting pretty at the top, all depending on what you’re after.

How do you pronounce Prusa printer?

To say Prusa without messing up, just cozy up to “Proo-sha.” Roll it off your tongue, and you’ll sound like a pro!

Do I have to use Prusa filament?

When it comes to Prusa filament, you’re not chained to their brand. Feel free to mix and match – they’re all about the open filament system, so let your filament flag fly!

Where are Prusa made?

Prusa printers are born and bred in Prague, Czech Republic – a city as beautiful as the print quality of their machines.

Where is the Prusa company located?

Prusa’s roots are firmly planted in the romantic city of Prague, Czech Republic – the land of castles, beer, and top-notch 3D printers.

Are 3D printers made in China?

While China has its fair share of 3D printers rolling off the assembly line, it’s a global party with many countries getting in on the manufacturing cha-cha.

Where is Prusa printer headquarters?

The Prusa printer headquarters, where all the magic happens, is nestled in the historical and stunning city of Prague, smack in the Czech Republic.